INTEGRATION SERVICE

The uSkin sensors can be integrated into both new and existing

robots.

In addition to providing the tactile sensors, XELA Robotics also

specializes in integrating them into various robot hand and

gripper applications.

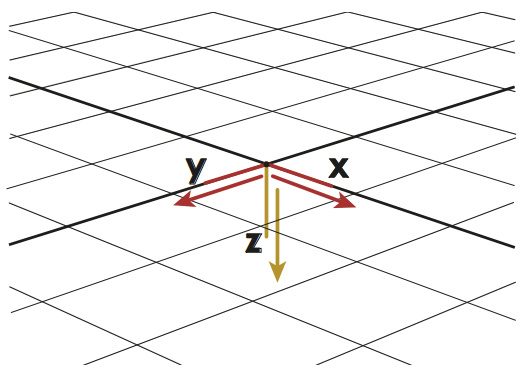

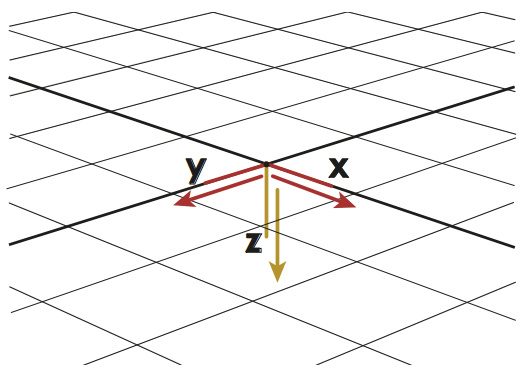

HIGH DENSITY 3-AXIS MEASUREMENTS

Each taxel in uSkin sensor mimics a joystick, measuring

X, Y and Z force:

•

Shear forces tangential to the surface

•

Normal force perpendicular to the surface

Providing you with a more detailed and accurate data

collection.

Tactile Sensor (XR1944) - Instruction Manual

July 2020

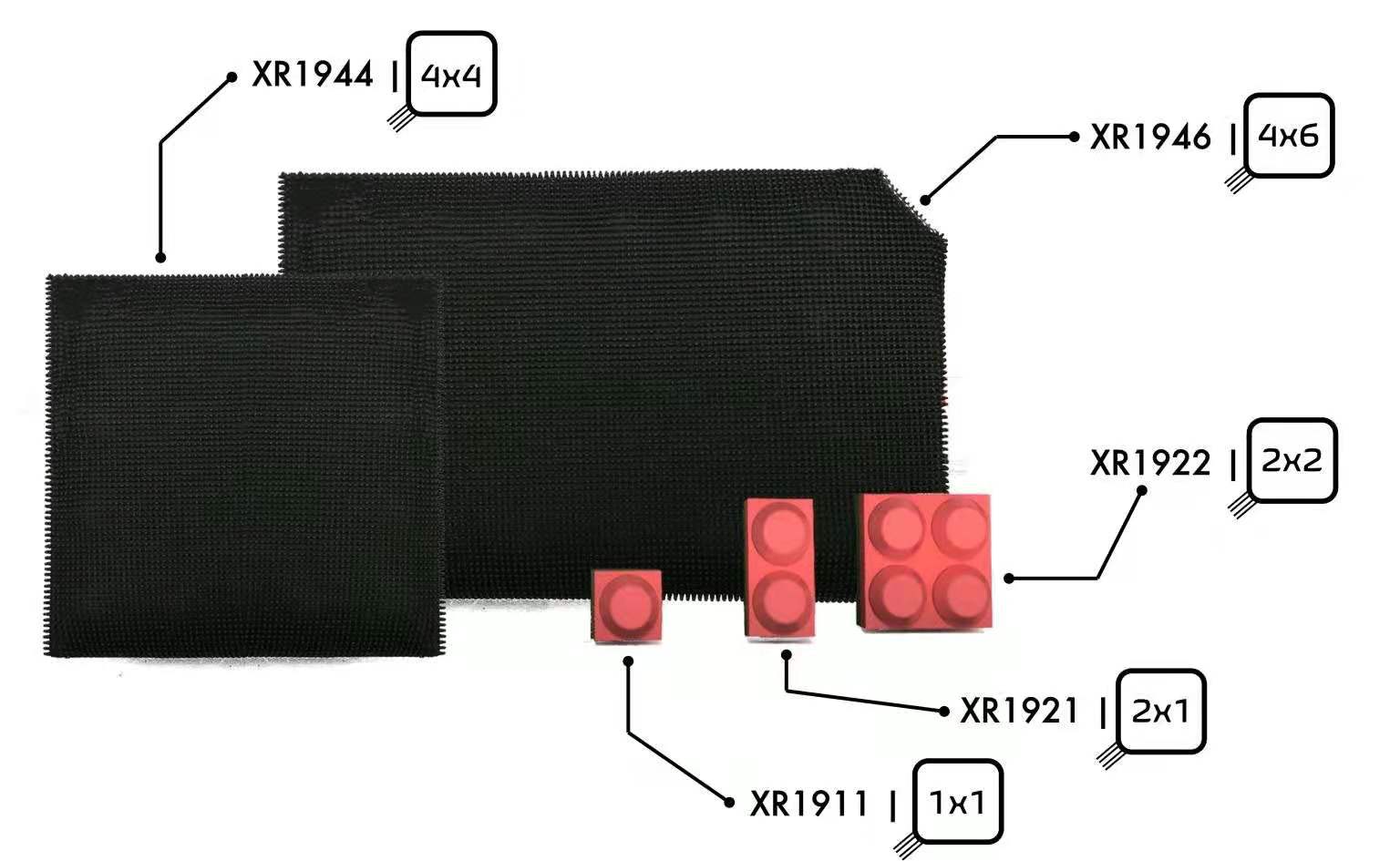

1 General Limitations for using the Sensors

• Applying too high forces or pressures will destroy the sensor module and will void the warranty.

Never apply more than 3 N z-axis force (force applied perpendicular to the sensor’s surface) to one

sensor cell (the XR1922 has 4 sensor cells, for example). Regarding x-axis and y-axis, the sum of

the shear forces has to stay below 15 kPa. These values are higher than the measurement range of the

sensor (given in the datasheet), as the sensor can be overloaded.

Furthermore, apply forces only to the sensor surface, not to the sides of the sensor module.

• As a skin sensor, the contact geometry always inflfluences the measurements. Therefore, we do not

calibrate the sensors, as any calibration would be valid only for the same contact shape. We suggest

that you use machine learning techniques or your algorithms to get various information out of the

sensor measurements, relevant for your application.

• As our sensor uses magnetic fifield changes induced by the skin deformation as its sensing principle,

other magnetic fifields (including the earth magnetic fifield), nearby magnets, or nearby ferromagnetic

materials can inflfluence the sensor measurements. Also crosstalk between two of our sensor mod�

ules is possible. Please confifirm within the inspection period (1 month from receipt of the product)

with your application if those inflfluences are prohibitory for your application. To counteract those

inflfluences, please also consider that a reference sensor could be used.

• Never bend the sensor modules. When you install the sensor modules on your robot, glue them to

a sturdy and flflat surface with thin double-sided sticky tape. Make sure to provide flflat support to the

whole backside of the sensor module.

2 Requirements

To collect data from the sensors, a PC with a USB 2.0 port is required. Both a Windows or Linux PC can be

used, as described in the "Software Manual". However, for the simple procedure to check if your sensors are

connected correctly to your PC, as described in this manual, a Windows PC is used. The software described

in this manual was tested on Windows 7 and Windows 10.

Our sensors work with various CAN-USB converters, as described on our webpage (https://xelarobotics.

com/en/canusb-adapters). This manual (in particular Section 4.2 and 5.1) is based on the software for the

CAN-USB/2 from ESD. The following CAN-USB devices are supported and tested.

• ESD CAN-USB/2 (bus: esd in Windows or socketcan in Linux)

• PEAK USB-CAN (bus: pcan, default channel: CAN_USBBUS1, Linux/ROS only)

• VScom USB-CAN Plus (bus: slcan, Linux/ROS only)

• CANable and CANable Pro (bus: socketcan, Linux/ROS only, with candlelight fifirmware) (Recom�

mended only for advanced users knowing CAN DSUB-9 pinout)

The software described in the "Software Manual" is based on Python. However, other programming lan�

guages can be used both for the server (which reads out the sensor data from the CAN bus) and the client

(which uses the sensor data). It is straightforward to use other programming languages for the client, as

they only have to connect to the server. For the server, while we only provide the server in Python, other

environments can be used, as long as they are compatible with the used CAN-USB converter. For example:

• ESD provides API for .NET, C#, Python, VC, Visual Basic, BC, LabVIEW, Linux, etc. Please refer

to ESD website for more information.

2 ©XELA Robotics• Peak System provides API for C#, Python, C, Visual Basic, Linux, etc. Please refer to PEAK System

website for more information.

3 Hardware Introduction

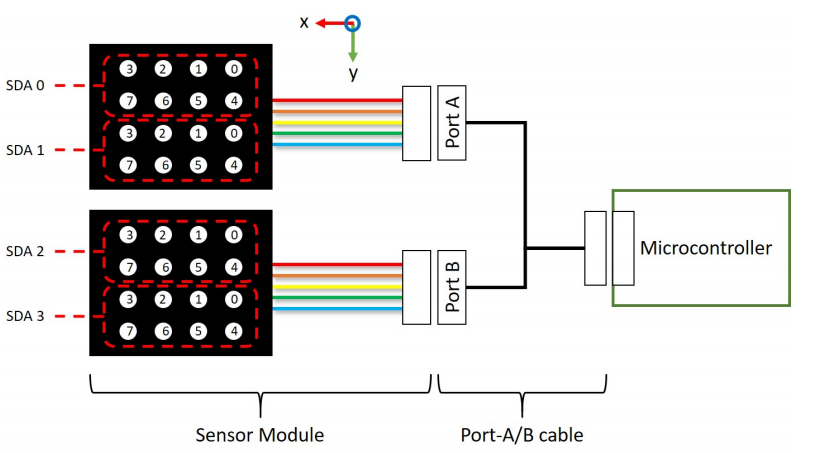

Figure 1: The connection between Sensor Module, Port-A/B cable, the microncontroller, and their respec�

tive SDA numbers and taxel numbers. The measurement axis is also shown here.

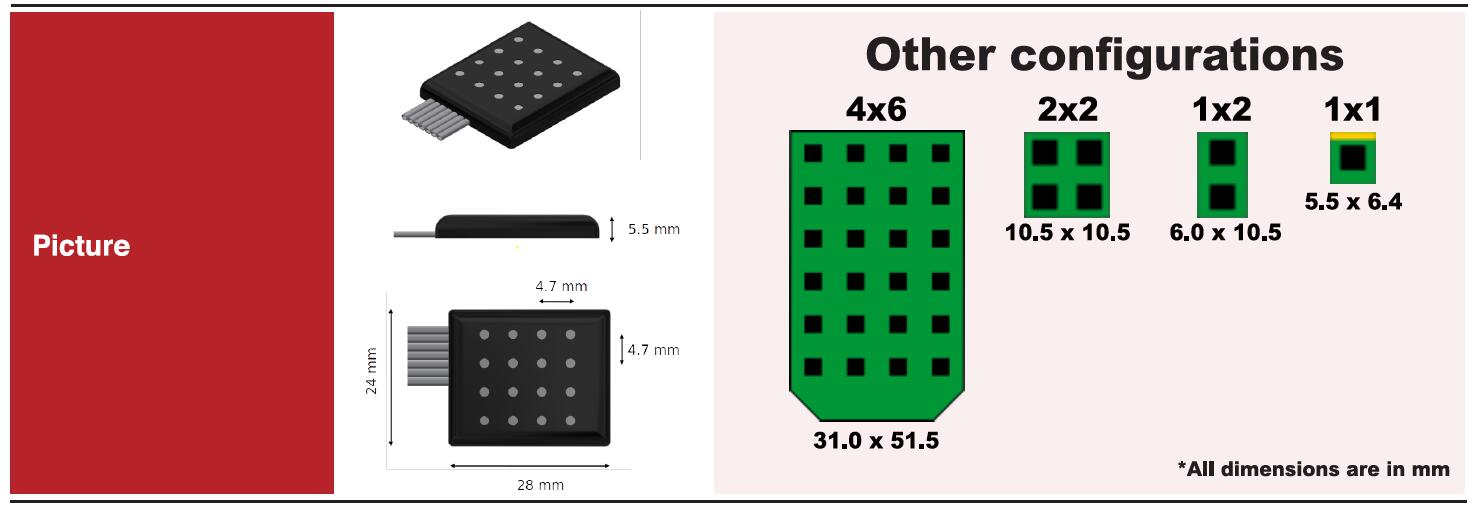

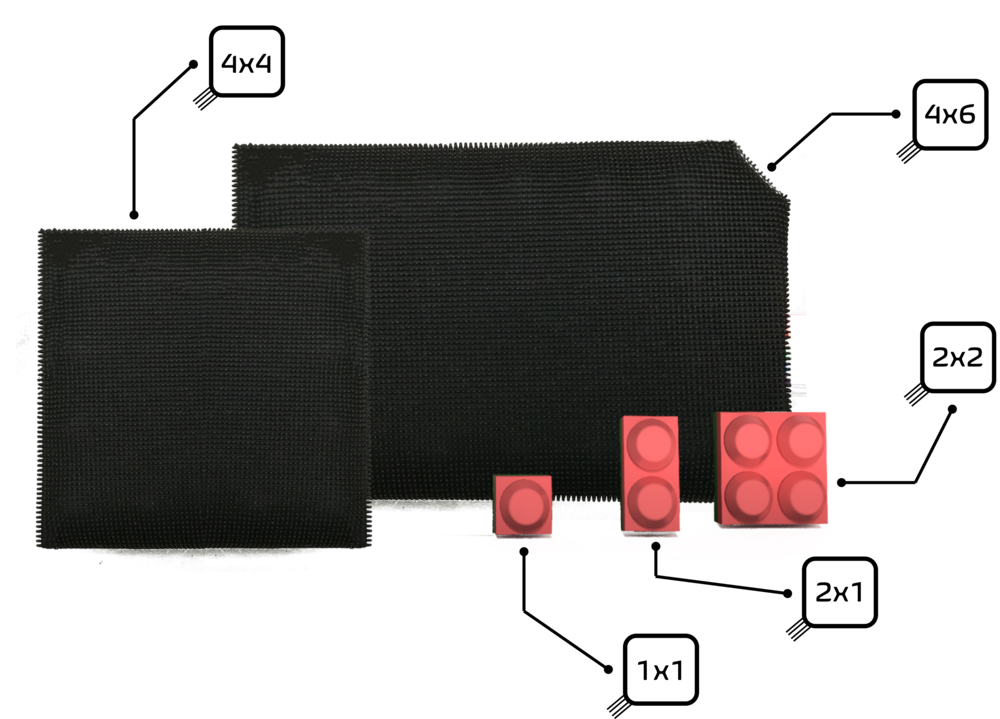

3.1 Sensor Module

Each Sensor Module has 16 sensing points (taxels) in total. Each taxel measures 3-axis skin deformation.

The sampling rate is 100 Hz. Each measurement has 16-bit (8 Most Signifificant Bit/ MSB and 8 Least

Signifificant Bit/ LSB) resolution per axis. Please see Figure.1 for the taxels’ number, their position, and

their respective SDA .

3.2 Port-A/B cable

The Port-A/B cable is used for connecting 2 Sensor Modules to 1 microcontroller. A label at the Port-A/B’s

end identify which Port a Sensor Module is connected to. Depending on this, the SDA number changes.

When a Port-A/B cable is not used to connect a Sensor Module to a microcontroller, it will be treated as

the Sensor Module is connected via Port-A. In other words, the SDA number of the Sensor Module will be

SDA0 and SDA1.

3.3 Microcontroller

The pre-programmed microcontroller is used to start the communication, confifiguring, and collecting the

data of the Sensor Module. The microcontroller can be connected to the Sensor Module through its 8-pin

port. In the current version of the Sensor Module, 2 of the module can be connected to one microcontroller

via the provided Port-A/B cable.

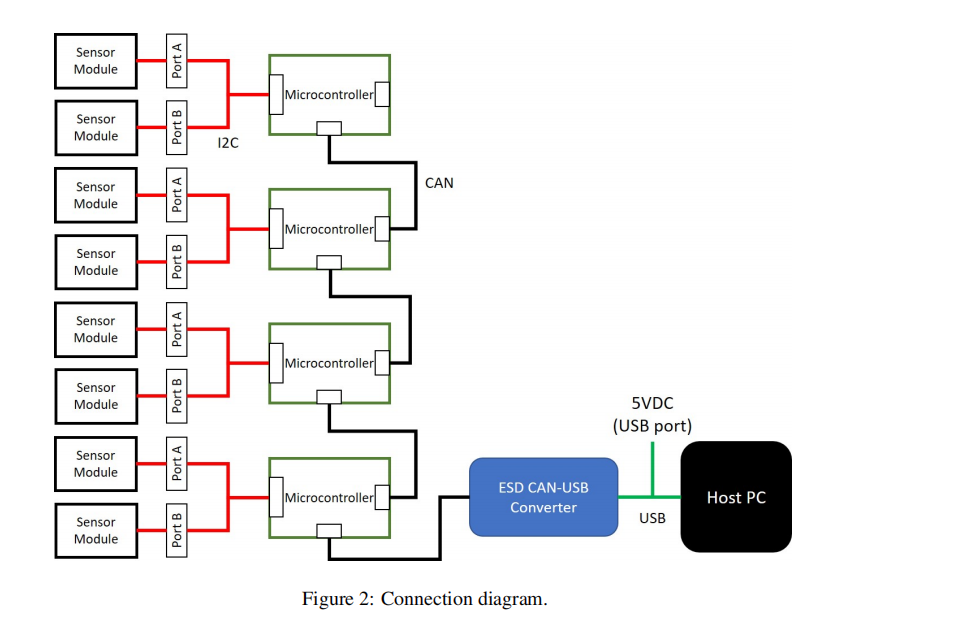

On the microcontroller, there are two 4-pin ports (VDD, D+, D-, GND). One of those ports is for the

communication between the microcontroller and the CAN/USB converter. The other one is for a daisy�

chain communication between microcontrollers through a CAN protocol. These ports are interchangeable.

Several microcontrollers with Sensor Modules can be daisy-chained.

3 ©XELA Robotics3.4 ESD CAN/USB Interface

3.4 ESD CAN/USB Interface

This device interfaces a PC with the microcontroller. It is connected to the PC with a serial bus (USB). This

device was developed by ESD and can be purchased separately from https://esd.eu/en/products/can-usb2.

The driver is also available from the given link.

3.5 CAN to DE-9 cable

This cable connects the microcontroller (4-pin connector) to the ESD CAN/USB converter (DE-9 connec�

tor). The 4 pin wires are for transmitting data to the ESD CAN/USB interface.

4 Setup & Installation

4.1 Connecting the hardware

1. Plug the 8-pin wires of one Sensor Module’s into a microcontroller. The Port-A/B cable can be used

to connect two Sensor Modules to one microcontroller.

2. Connect the 4-pin connector of the CAN/DE-9 cable to 1 of the 2 4-pin port of the microcontroller.

3. Connect the DE-9 connector of the CAN/DE-9 cable to the CAN/USB Interface.

4. Plug the USB cable of the CAN/USB Interface into any of the USB ports of your PC.

5. Plug the USB power cable of the CAN/DE-9 cable into a PC or USB wall adapter (5V). The power

indicator (blue LED) of the microcontroller should be on.

4.2 Driver and Libraries Installation

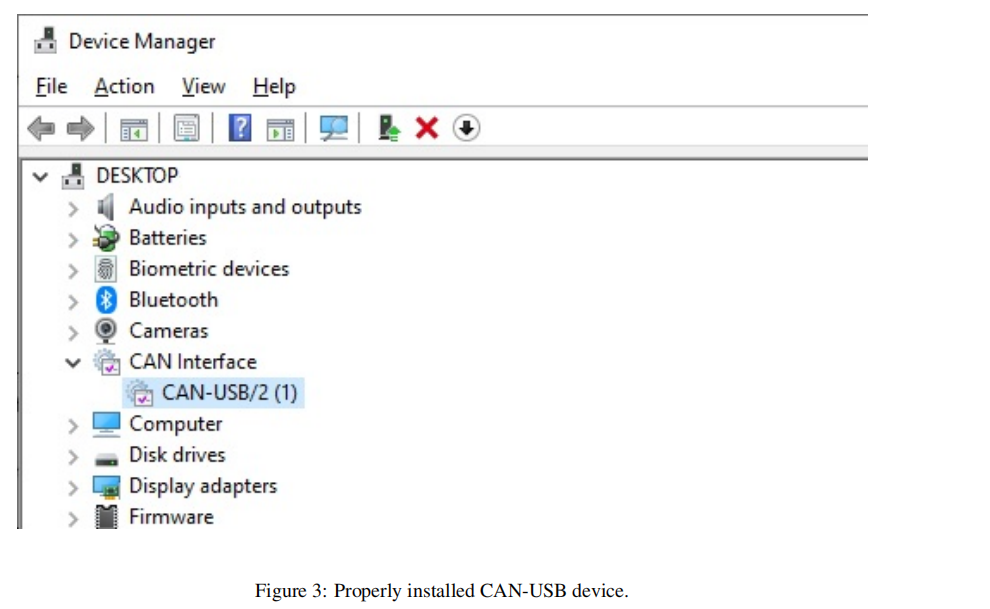

4.2.1 ESD CAN/USB driver

After plugging in the USB cable, open the device manager from the control panel. In the USB section,

make sure that the device is detected as an unknown device. Right click the unknown device and specify

the driver location to the CAN USB Driver folder (...\CAN USB Driver). The driver can be downloaded

4 ©XELA Roboticsfrom the ESD website or can be found inside the installation CD. If it is successful, the unknown device

should turn into "CAN Interface - CAN USB/2" as in Fig. 3.

4.2.2 CAN SDK

Run CAN_SDK.exe from ...\CAN USB driver\CAN_SDK and follow the instructions. This will install the

ESD CAN/USB libraries and sample programs required for the next step.

5 Explanation of CAN ID and CAN message

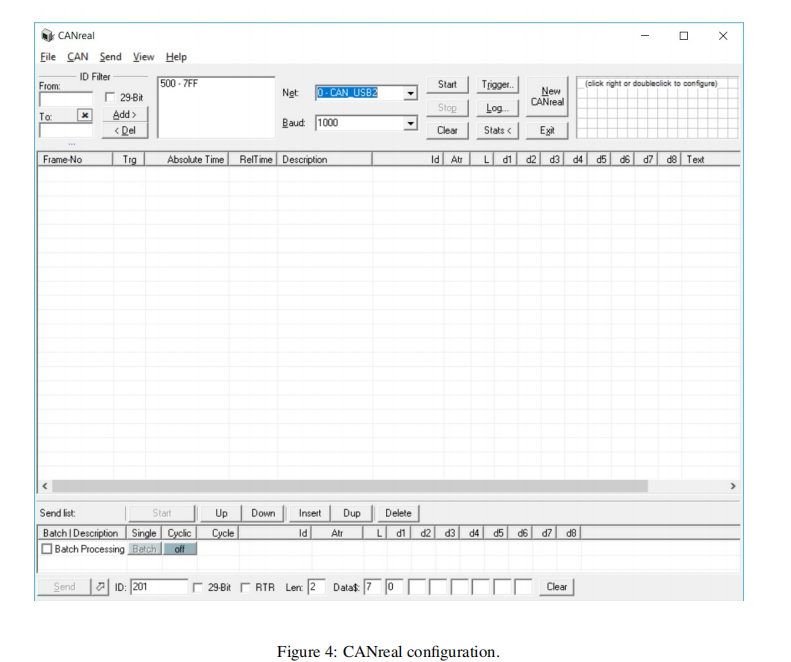

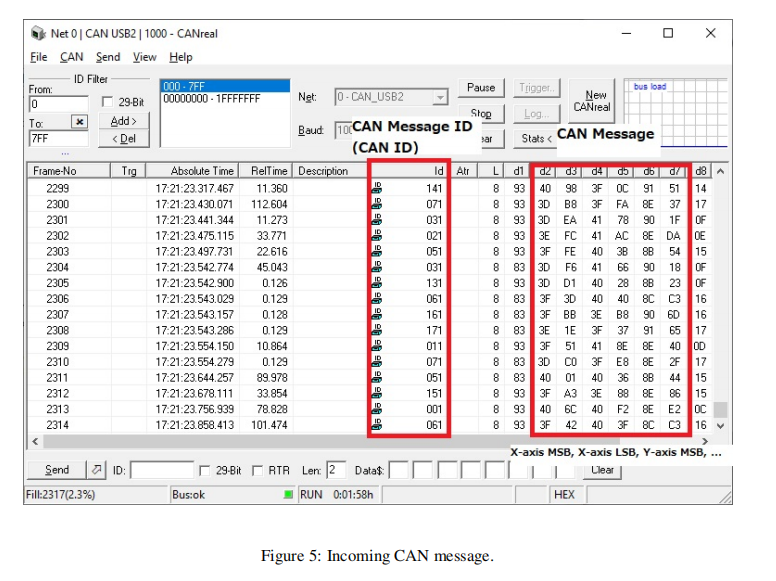

5.1 CANreal

Here we use CANreal application provided by ESD to make the explanation easy to understand. Run the

CANreal application. The application is installed as part of SDK and can be found by default at C:\Program

Files\ESD\CAN\SDK\bin32\CANreal. Confifigure it as in Fig. 4.

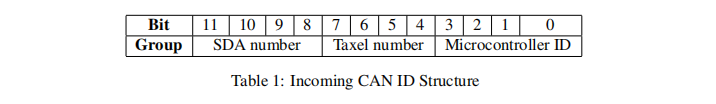

5 ©XELA Robotics5.2 Incoming CAN ID structure

select a detected CAN/USB device by choosing it from the "Net" drop-down menu. If there is nothing that

can be selected, the device may not be plugged or the driver is not installed properly. Confifigure the "Baud"

to 1000 then click "Start". A Successful connection will lead to an incoming CAN Message as in Fig. 5. At

this point, your PC is ready to run our sample code.

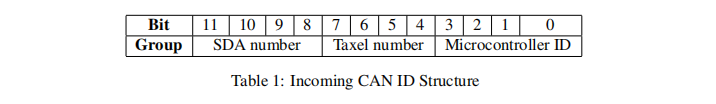

5.2 Incoming CAN ID structure

Each incoming CAN message comes with its ID. The ID represents the number of microcontroller and the

taxel of the Sensor Module connecting to that microcontroller. The meaning of the ID is as shown in Table

• "Microcontroller ID" is pre-defifined. The number can be found on each microcontroller.

• "SDA number" is defifined from whether Port A or Port B of the Port-A/B cable that the Sensor

Module is connected to. If a Sensor Module is connected to Port A, the SDA number will be 0 and 1

depending on the position of the taxel. See Figure 1 for more detail.

• "Taxel Number" is defifined as in Figure 1.

Therefore, the incoming CAN IDs of the taxels on the Sensor Module which is connected to the microcon�

troller ID1 via Port A, are as follow.

• SDA 0 Taxel 0 - 3 : 0x001 - 0x031

• SDA 0 Taxel 4 - 7 : 0x041 - 0x071

• SDA 1 Taxel 0 - 3 : 0x101 - 0x131

• SDA 1 Taxel 4 - 7 : 0x141 - 0x171

For the Sensor Module that is connected via Port B of the same microcontroller ID1, the incoming CAN

IDs of the taxels are as follow.

• SDA 2 Taxel 0 - 3 : 0x201 - 0x231

• SDA 2 Taxel 4 - 7 : 0x241 - 0x271

• SDA 3 Taxel 0 - 3 : 0x301 - 0x331

• SDA 3 Taxel 4 - 7 : 0x341 - 0x371

Note that if a Sensor Module is connected directly to a microcontroller without any Port-A/B cable, it will

be treated as connecting to Port A.

5.3 Incoming CAN Message structure

Each incoming CAN message contain 8-byte data. The data compose of 3-axis components of contact

measurement. The structure of the data is as follows.

• 1st byte : Not used

• 2nd byte : X-axis MSB

• 3rd byte : X-axis LSB

• 4th byte : Y-axis MSB

• 5th byte : Y-axis LSB

• 6th byte : Z-axis MSB

• 7th byte : Z-axis LSB

• 8th byte : Not used

By combining the MSB and LSB part of each axis, the 16-bit measurement can be acquired.

共0条 [查看全部] 网友评论